Water Well Tips - from a homeowner

Adjusting Your Water Well

Pressure Gauge needs to be mounted vertically to prevent water intrusion. If it gets very cold and water freezes inside the gauge, the Bourdon tube will be damaged. This can cause it to add an extra 30 psi to all readings, which is confusing. Having the gauge upright is better to read and keeps the water out. Oh yeah, if it freezes, it's best if the plumbing is insulated with pipe wrap, or the like.

I learned these lessons the hard way.

Well Cap should not be loose. The cap is a sandwich of steel plates with a rubber seal that gets squished and becomes wider, sealing itself in the well tube. It is possible for the cap on a new installation to become loose after the rubber forms to its new shape and takes a set.

The fasteners on top (4 nuts on mine) should be evenly tightened. Don't over-tighten it, think valve cover gasket, not lug nuts.

Bladder Tank Pre-charge needs to be set correctly. Properly pressurized bladder tank is adjusted to 2 psi below the pump switch cut-in pressure. This is done with the system at 0 psi (open). Using a 40/60 pump switch setting and a 38 psi pre-charge is a typical setup. This setup ensures that the system pressure doesn't drop off and make it difficult for the pump to restart.

Checks and Adjustments - here is a safe procedure for the mechanically inclined individual. Note, strong fingers may be required for manipulating the pump switch lever.

Read entire procedure first, make sure you are comfortable with it. Water and electricity don't mix well. Have a clear head.

A) You may want to turn off the electrical power to the well.

B) Turn off pump switch. It's a small lever on the side. Mine goes up to switch from the auto to off positions.

C) Drain the bladder tank. You should have bib on the plumbing. Connect a hose and drain it somewhere good.

D) Make any plumbing repairs, such as mounting your gauge on a nice, vertical riser tube.

E) Check and adjust the bladder tank pre-charge pressure. It should have a Schraeder valve on top. https://en.wikipedia.org/wiki/Schrader_valve

F) Close the bib.

G) Turn power back on and restart the pump switch.

Pump Switch

There is a little trick for restarting the pump switch. Basically, you hold it in the halfway position while the pump restarts and then move it to auto. This is necessary when you are restarting from 0 psi. You have to overcome the diaphragm spring pressure since the switch operates between 40 and 60 psi. There will be some resistance.

I like to remove the pump switch cover and watch the contacts when I do this but I said safe, so, wear some leather gloves once you get it open - as there will be exposed 240V AC.

Move the small pump switch lever slowly from the "off" towards the "auto" position. It will feel like the resistance of an eccentric cam. About half way, one of the two pairs of contacts will close, you may see a small blue spark, hold steady. The pump will start audibly and the resistance in the lever fades as the pressure builds. Now, push the lever the rest of the way to the "auto" position and carefully replace the switch cover. Smile.

H) Watch the pump cycle on the pressure gauge. You can open the bib to drain it after it clicks off. Watch and listen. The gauge should move between the 40 and 60 psi set points. When the well restarts, there should be a click followed by a hum, maybe some gushing sound and slight vibration. It's pretty smooth if setup correct. Otherwise you can have a big clunk or no restart.

I) The pressure switch can be adjusted, if necessary. There are two nuts. One changes both settings. The other changes just the lower. Details for this are printed inside the switch cover, usually. Do wear gloves around the live, uncovered switch and take care when draining the system for restarting.

rural wells

mountain well

mountain water

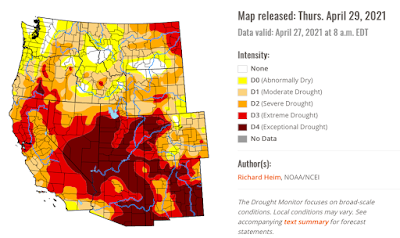

see the current drought map for California